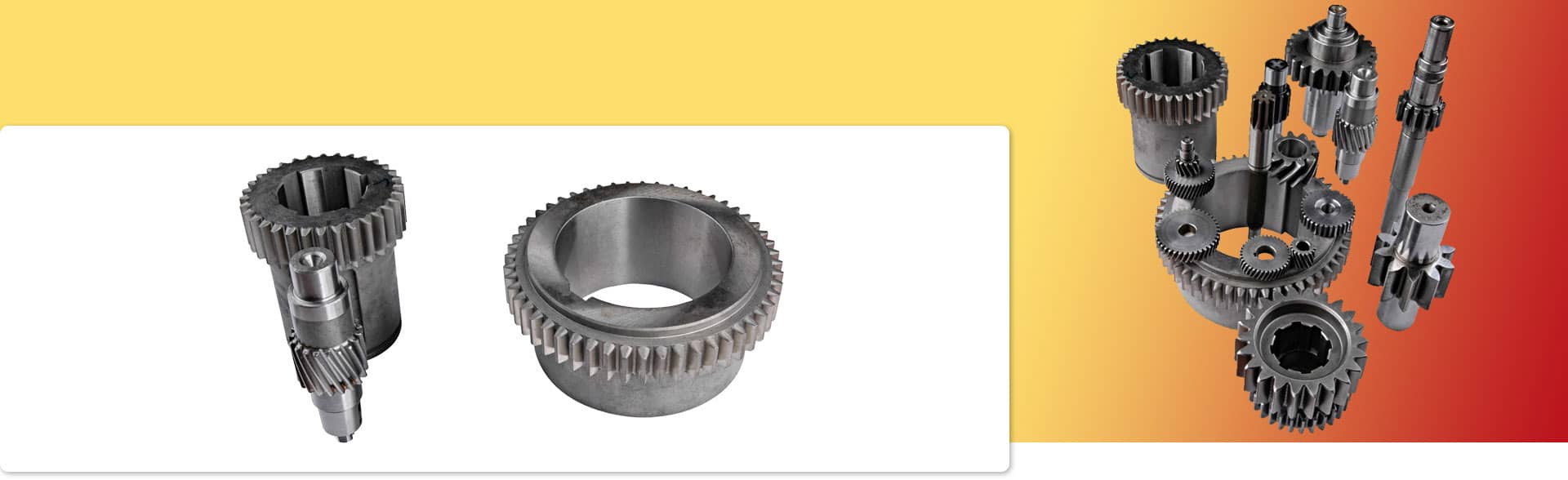

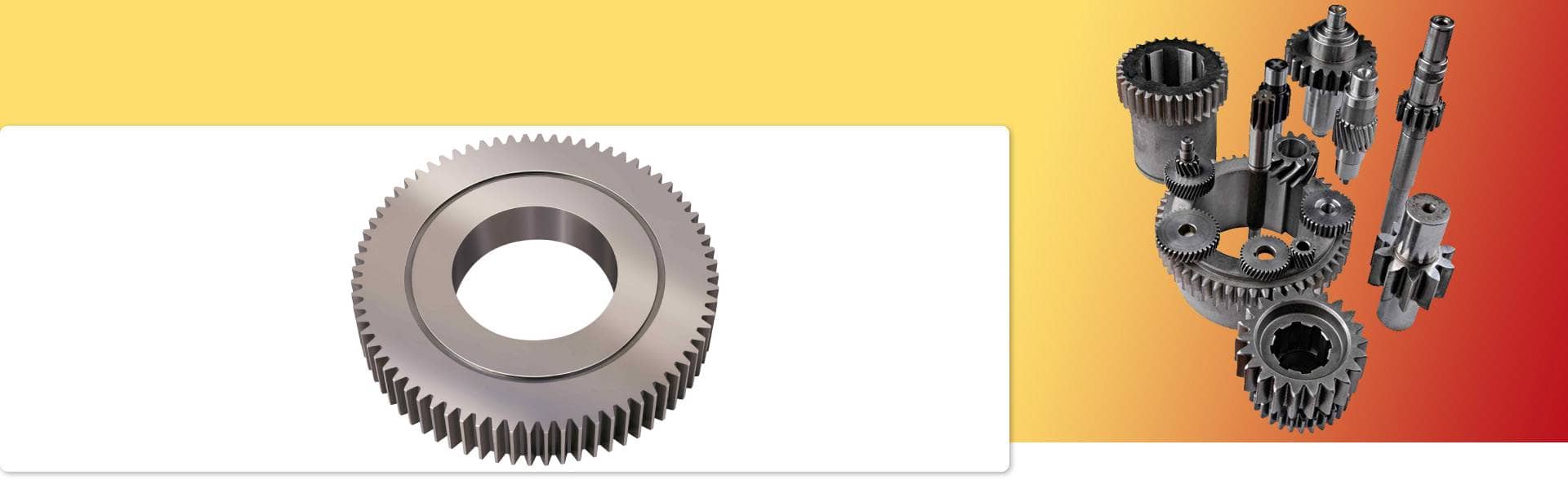

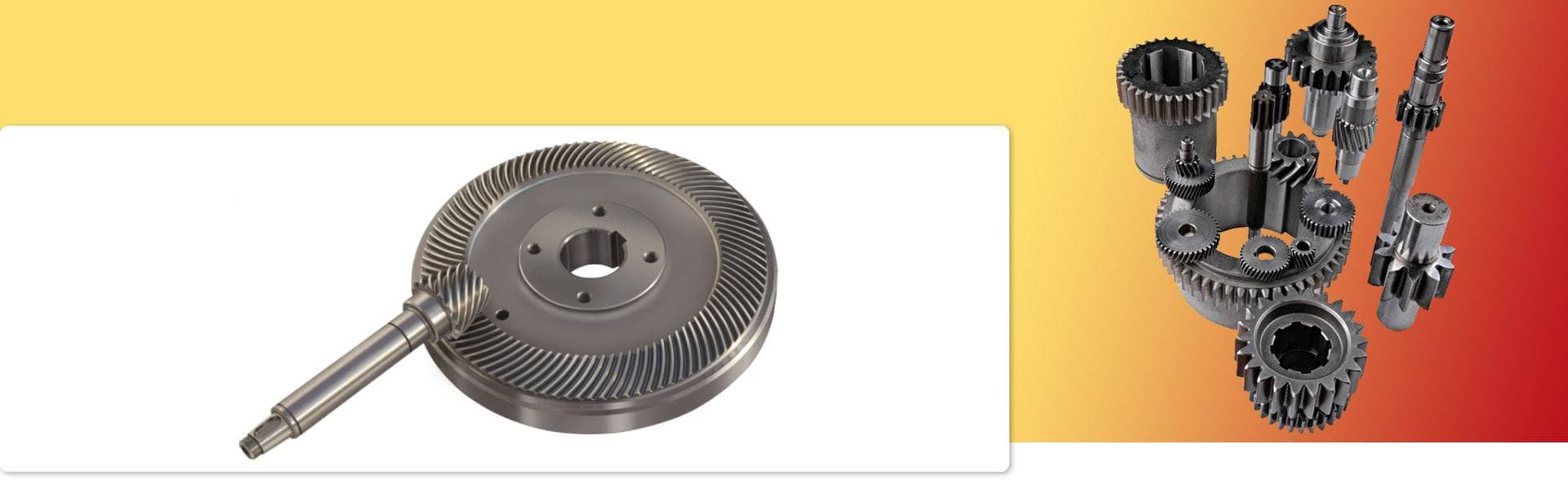

Spur Gear

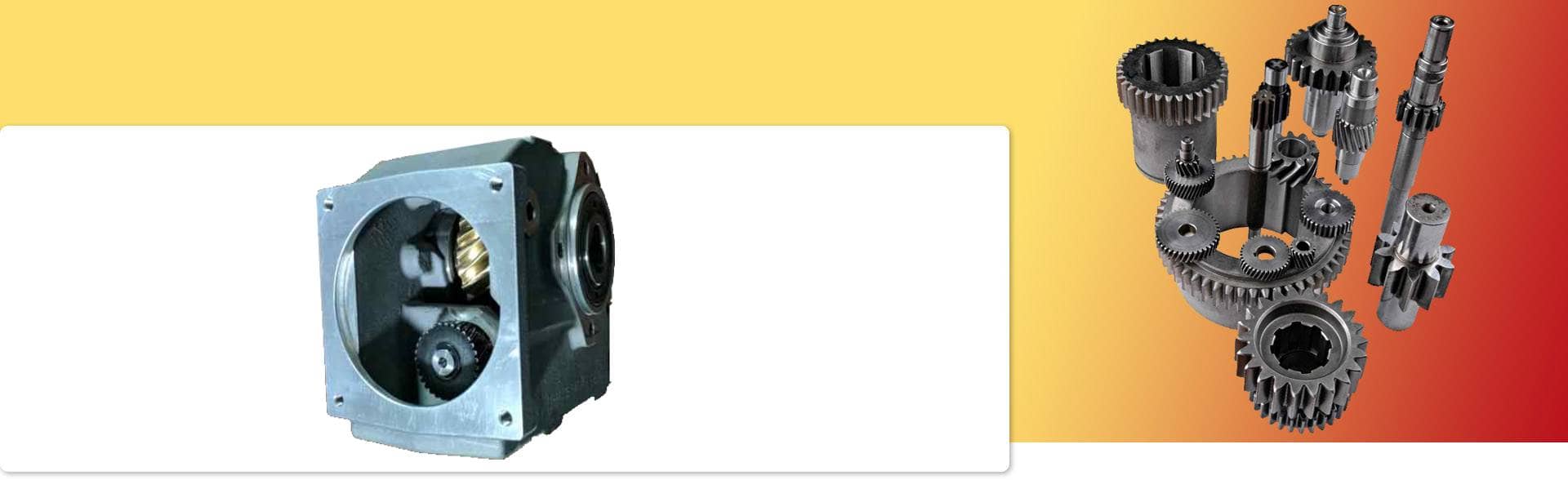

Spur gears are one of the simplest and most widely used types of gears. Their general form is a cylinder or disk. The teeth project radially, and with these "straight-cut gears", the leading edges of the teeth are aligned parallel to the axis of rotation. These gears can only mesh correctly if they are fitted to a parallel axle. We manufacture durable and highly efficient Spur Gears up to 150 mm OD & 3.5 module in steel. These gears are essential components in Gearboxes used in Machine Tools, Material Handling Equipment, and Gear Pumps.

Characteristics of Spur Gears

Spur gears connect parallel shafts and feature involute teeth parallel to the shaft. These gears can have either internal or external teeth and are known for causing no external thrust between gears. Due to their straightforward design, spur gears are inexpensive to manufacture, providing a cost-effective yet satisfactory performance, especially when the shaft rotates in the same plane. The key features of spur gears include the dedendum, addendum, flank, and fillet.

The dedendum cylinder is a root from where teeth extend; it extends to the tip called the addendum circle. Gears for all applications can be produced to customers' design.

For a detailed overview of gear-related terms, Enquire Spur Gear Guide

Applications of Spur Gears

Automotive: Powering transmissions, engines, and drive systems, our spur gears provide exceptional reliability and performance.

Aerosopace & Aviation: Spur gears are vital for aircraft engines, landing gear and other critical systems.

Industrial Automation: From CNC machines to conveyor systems, our gears ensure smooth operation, reducing the need for maintenance.

Construction Equipment: Heavy machinery like excavators, cranes and loaders for power transmission and movement.

Custom Spur Gears for all Applications

We specialise in manufacturing spur gears tailored to our customers' specific designs, ensuring that they meet the unique requirements of their applications. Whether you need standard spur gears or custom gear solutions, Pragati Transmission is here to help. We offer quick delivery, competitive pricing and high-quality manufacturing for all kinds of indsutries worldwide.

Enquire Now